Q&A: How Fulton is Re-Inventing Insoles Using All-Natural Materials

We caught up with the founders of Fulton, a brand creating sustainable and supportive insoles. They shared the problems that led them to starting Fulton, the reasons they use plant-based materials over synthetic materials, challenges they’re facing, and more.

Enjoy the interview, and make sure to leave any questions in the comments section at the end of the article.

Hello! Who are you and what brand do you run?

We’re Libie Motchan and Daniel Nelson, and we are the founders of Fulton.

What led you to starting Fulton?

We started Fulton after realizing that the foot and back pain that we experienced on a daily basis was caused by our unsupportive footwear. We spoke to podiatrists, chiropractors, researchers, and engineers who all explained that arch support was critical to feeling our best, yet sorely lacking from the footwear we wore.

The insole industry was full of products ranging from $10 to $1,000, and customers didn’t know which they should trust. Expensive ones were overly medical and inaccessible. Less expensive insoles were made from ineffective and unsustainable materials like gels and foams.

We launched Fulton to cut through the noise, explaining the benefits of arch support through a modern brand and an effective product.

Most insoles are made from synthetic materials: why did you choose all-natural, plant-based materials?

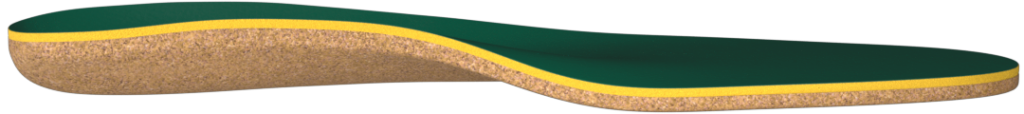

We rejected the idea that insoles had to be made from unsustainable gels, foams, and plastics just because other leading brands chose to use those materials. Instead, we performed extensive research on materials, testing dozens to find the perfect combination for our product until we landed on cork, natural latex foam, and vegan cactus leather.

Beyond being great for the environment, each layer works together to provide a functional benefit to the product.

The cork foundation allows the insole to mold to the shape of the wearer’s foot, providing a more customized walking experience.

The natural latex foam makes the insole incredibly comfortable to stand on for many hours at a time.

Lastly, the cactus leather layer is a premium vegan leather that serves as a great alternative to other vegan leathers that are often made from plastics.

Cork harvesting, does not cut down the tree, the tree must first grown for 25 years, then the tree regenerates cork which is harvested every 9 years.

How do you ensure your materials come from sustainable sources, and how did you choose suppliers?

After aligning on our materials, we searched for suppliers and performed diligence in several ways. For some, we vetted them by visiting factories and understanding their processes for manufacturing. For others, we asked to see evidence of upholding the highest sustainability standards from third parties – either through trusted sustainability certifications or lifecycle analysis (LCA) outputs.

Although we are proud of what we’ve achieved so far, we’re always striving to improve. We’re currently conducting our own lifecycle analysis and searching for ways to push our brand closer to circularity.

In your eyes, what’s the biggest achievement or milestone you’ve acheived so far?

Although our two-plus-year journey so far has been full of rewarding achievements and milestones, we believe that successfully creating and launching this product has been the greatest. We weren’t sure how consumers would react to an insole made from novel, sustainable materials and have seen the most promising results.

95% of our customers intend to purchase additional pairs for their shoes, and our return rates are lower than the norms for insoles, footwear, and ecommerce.

Furthermore, we get tons of messages from customers thanking us for this product, explaining that our insoles are equally if not more effective than the $500 insoles they used to purchase from their podiatrist or chiropractors. These data points show us that the product we created is resonating, which is by far the greatest milestone we could have achieved to date.

What do you think the main challenges around sustainable production are today? How does Fulton approach these on a day-to-day basis?

The biggest challenge is that sourcing sustainable materials that are effective, affordable, and scalable is incredibly difficult for consumer brands.

The footwear/insole markets are oriented around the unsustainable gels, plastics, and foams we were trying to avoid.

As a result, we had to search for materials in other industries to create our insoles. Since this was a priority for us, we spent roughly a year getting the material mix right.

Still, many brands recognize the limitations in their respective industries and are forced to take shortcuts to prove demand and improve their materials down the line.

A problem in sustainable production is the cost behind completing a lifecycle analysis, and understanding the true impact of a business’s operations.

Another smaller yet looming problem in sustainable production is the cost behind completing a lifecycle analysis (LCA), and understanding the true impact of a business’s operations.

Many brands may want to know how sustainable they are and where they can improve but can’t invest tens of thousands of dollars at such an early stage. We did as much upfront research as we could before selecting suppliers and are now partnering with another startup piloting a more efficient LCA process.

Have you tried a product from another sustainable brand that you can recommend?

We love Thousand Fell – they’re a sustainable footwear brand that created a completely circular, stylish shoe. Moreover, Thousand Fell sneakers have removable insoles, meaning they’re great shoes to use Fulton insoles with!

What does the future look like for Fulton?

We believe that all shoes should have proper arch support and plan to build our company around this thesis.

First, that means more products: there are many other types of footwear out there lacking arch support that our current insoles might not fit in. We’re currently working with customers to understand these use cases and guide our future product development.

Second, getting arch support in all shoes means expanding the places where more customers can buy them. We currently sell primarily through our online store, but recognize the power that tapping into other e-commerce and retail networks could spread Fulton awareness.

We’re currently thinking through a roadmap and how we approach additional partner retailers down the line.

If readers have never worn insoles, why should they wear them? And why Fulton?

All shoes come with an insole – the issue is that almost none of them support your body correctly. The lack of arch support creates misalignment across your feet, knees, hips, and back, leading to pain and discomfort over time. Proper arch support helps align the body and promote healthy walking. In the hundreds of millions of steps you’ll take throughout your life, the impact footwear without arch support will add up!

We created Fulton to take the confusion out of adding proper support to your daily routine. Fulton insoles are comfortable, supportive, and sustainable, molding to the shape of your feet to provide support the way your body wants it.

Wrapping Up

We hope you found this Q&A interesting. If you have any questions about Fulton, you can learn more on their website, or, leave a question in the comments below.

Fulton insoles offer a zero risk investment in your wellness: they offer free shipping, free exchanges, and free returns to make your introduction to arch support as convenient as possible.

If you want to check them out, you can do so via the link below!